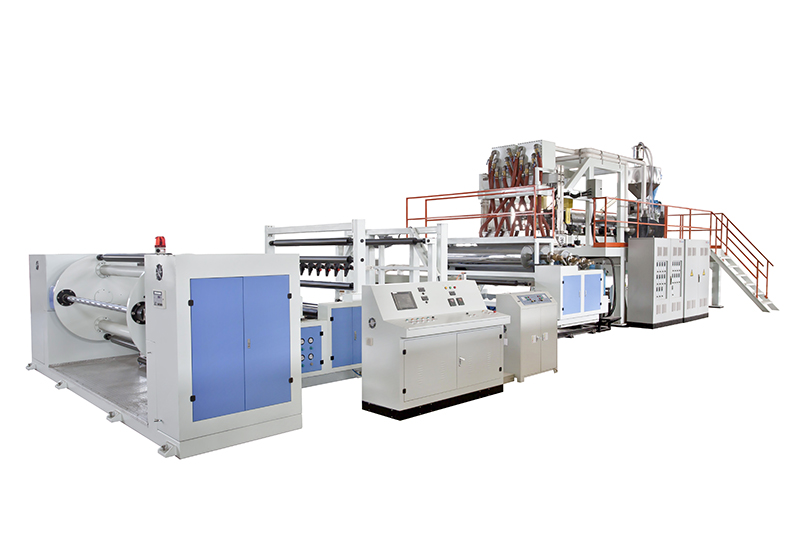

Stone Paper Production Line – Wellson

Stone Paper Production Line – Wellson Detail:

*INTRODUCTION

Stone paper is made from crushed limestone powder mixing with PE or PP resins as binding agent. While the base ingredient is Calcium Carbonate (CaCo3), stone paper is an extremely environmentally friendly paper and totally different from traditional wood-pulp paper.

The stone paper production is made up of three processes: pelletizing, base paper production and coating process. Base paper production is the key process and our technology is cast film with MDO stretching.

We offer the turn-key project for stone paper production, supplying full equipment, transferring know-how and training operators.

*Advantages & Features

1) Equipped with in-line CaCo3 compounding, the line can use CaCo3 powder directly, and save great power consumption.

2) Much higher output capacity than those traditional machines.

3) Avoid the problem of CaCo3 powder release.

*Technical Data

| Model No. | Product Width | Product Thickness | Output per Hour | Installed Power |

| WS120/90-2200 | 1400mm | 0.03-0.30mm | 500-800kgs | 600kw |

| WS150/110-3000 | 2200mm | 0.03-0.30mm | 800-1500kgs | 850kw |

| WS180/150-4000 | 3200mm | 0.03-0.30mm | 1000-2000kgs | 1000kw |

Remarks: Other sizes of machines are available upon request.

*Application

1) Printed materials: notebook, envelop, business card, poster, map, manuals, calendar, labels and tags etc.

2) Packaging product: wrapping paper, packing bag, packing box, etc.

3) Decorated paper: wall paper

4) Disposable goods: garbage bags, disposal tablecloth, shopping bag, food wrap bag, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Stone Paper Production Line – Wellson , The product will supply to all over the world, such as: UK, Costa Rica, Uzbekistan, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We are looking for the wholesale, Drop ship. Please contact us if you are interesting our products. Hope to do business with you all. High quality and fast shipment!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.