Rapid Delivery for Pe Extrusion Coating And Laminating Line - Non Woven Extrusion Coating Laminating Line – Wellson

Rapid Delivery for Pe Extrusion Coating And Laminating Line - Non Woven Extrusion Coating Laminating Line – Wellson Detail:

*INTRODUCTION

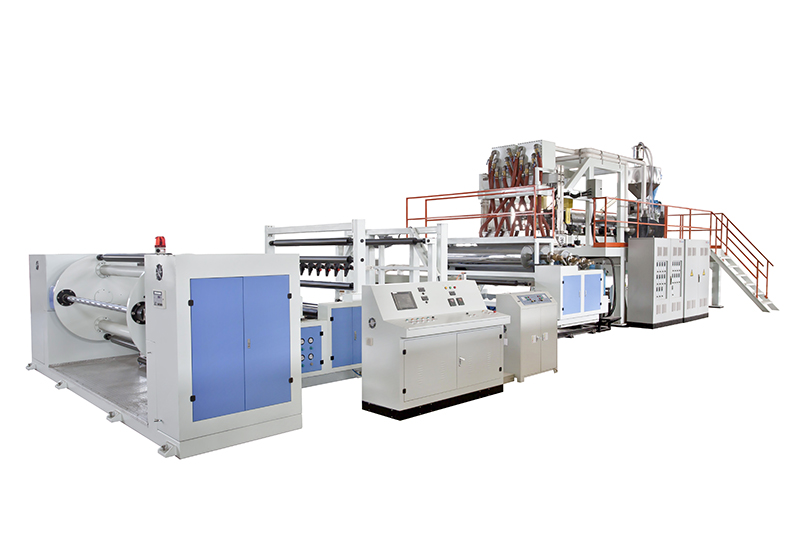

Non woven extrusion coating laminating line is equipped with high-performance extruder, chrome-plated chill roll, and fully-auto unwinder and winder. The extruder coats PE polymer materials onto a substrate of nonwoven fabric and make nonwoven composite without using any glue.

The line can also be equipped with 2 or 3 extruders, to make sandwich laminating or double-sided coating. The final product thus have all the properties from both nonwoven fabric and PE polymer, for example, textile feeling, water proof etc.

Non-woven Extrusion Coating Lamination line is an innovative extrusion coating and laminating machine with latest intelligent PLC control system. This laminating line is designed for processing PP/LDPE material for multiple coating applications like coated non woven fabric and flat fabric of PP or LDPE, single or double side coating. Best workmanship, innovative technology and modular design, allows high cost efficient production at highest output and maximum flexibility, meeting the most sophisticated demands of modern packaging technology.

Coatings are applied to non-woven fabrics to make them waterproof, flame resistant, antistatic and printable. A coated fabric offers better protection against wind, water, cold temperatures and chemicals. During this process, a liquid coating layer is fixed onto a woven or non-woven fabric. This extruded layer can be applied on one side, both sides, or in multiple layers.

*Machine Details

Product width: any option from 1200mm to 3500mm, upon request

Coating Resin: LDPE, LLDPE, EVA

Substrates: nonwoven fabric, woven fabric

Diameter of Unwinding: Φ1200mm max.

Diameter of Winding: Φ 1000mm max.

*Application

The typical application of nonwoven coating / laminating will be textile-like diaper backsheet, table cloth, nonwoven bag, medical gown, medical drapes, hospital products etc.

Product detail pictures:

Related Product Guide:

Cooperation

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Rapid Delivery for Pe Extrusion Coating And Laminating Line - Non Woven Extrusion Coating Laminating Line – Wellson , The product will supply to all over the world, such as: Casablanca, Australia, Ghana, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.