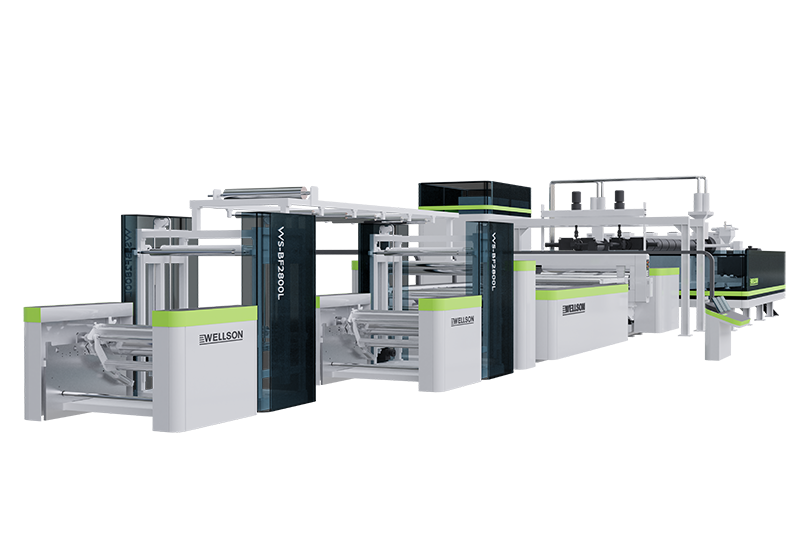

China Factory for Microporous Film Production Line - Cast Embossed Film Line, Hygiene Film Line – Wellson

China Factory for Microporous Film Production Line - Cast Embossed Film Line, Hygiene Film Line – Wellson Detail:

*INTRODUCTION

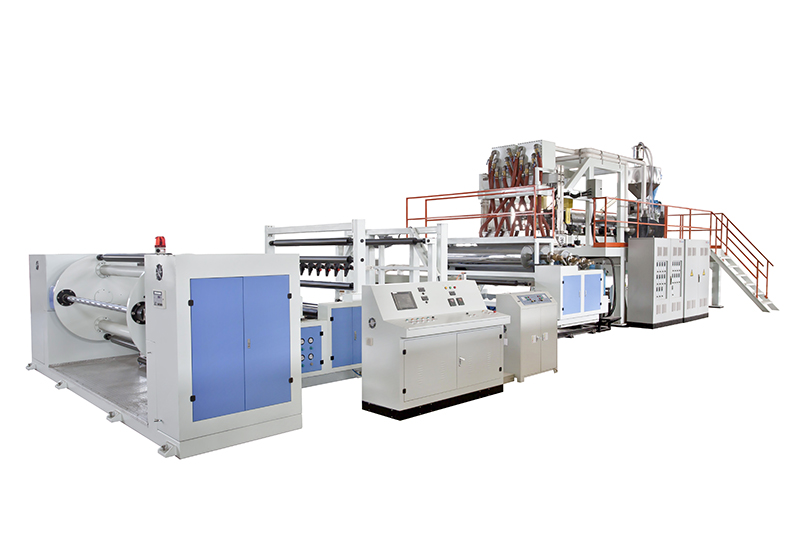

Cast embossed film line produces melt embossed films for hygiene, medical and packaging applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs.

The extruder converts polymers into continuous melt resin, and then T die make it as film curtain. Through such a cast film extrusion system, an engraved steel roll and silicon rubber roll are installed at the casting cart of the line. When the melt resin curtain comes out of T die, it is pressed onto the embossing roll by silicon roll to produce embossed film. The film embossing patterns can be designed upon existing samples or customers’ request. The changeover of embossing patterns is quick and easy by replacing the calendaring rollers only. As a result of embossing surface, they are technical films used in a lot of industries. Wellson Machinery has long years’ experiences of manufacturing cast embossed film lines for customers worldwide. Our technology and know-how help our customers to develop value-added products for the markets.

Our cast embossed film machines are operated and controlled by advanced PLC system and HMI system. Our machines are a combination of high-speed production and low power consumption due to advanced machine designs. They are best machine solutions for manufacturers of technical films

*APPLICATION

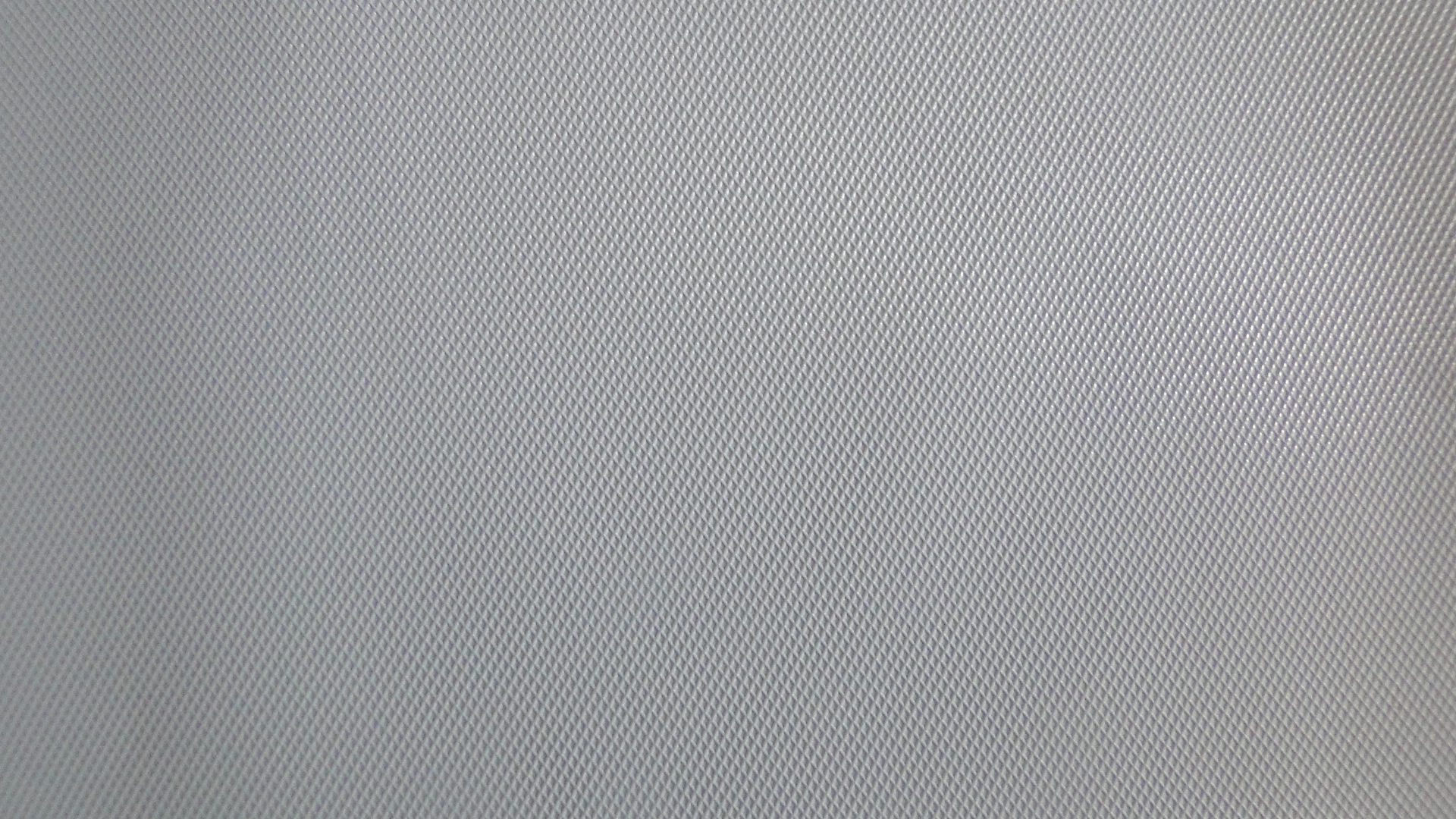

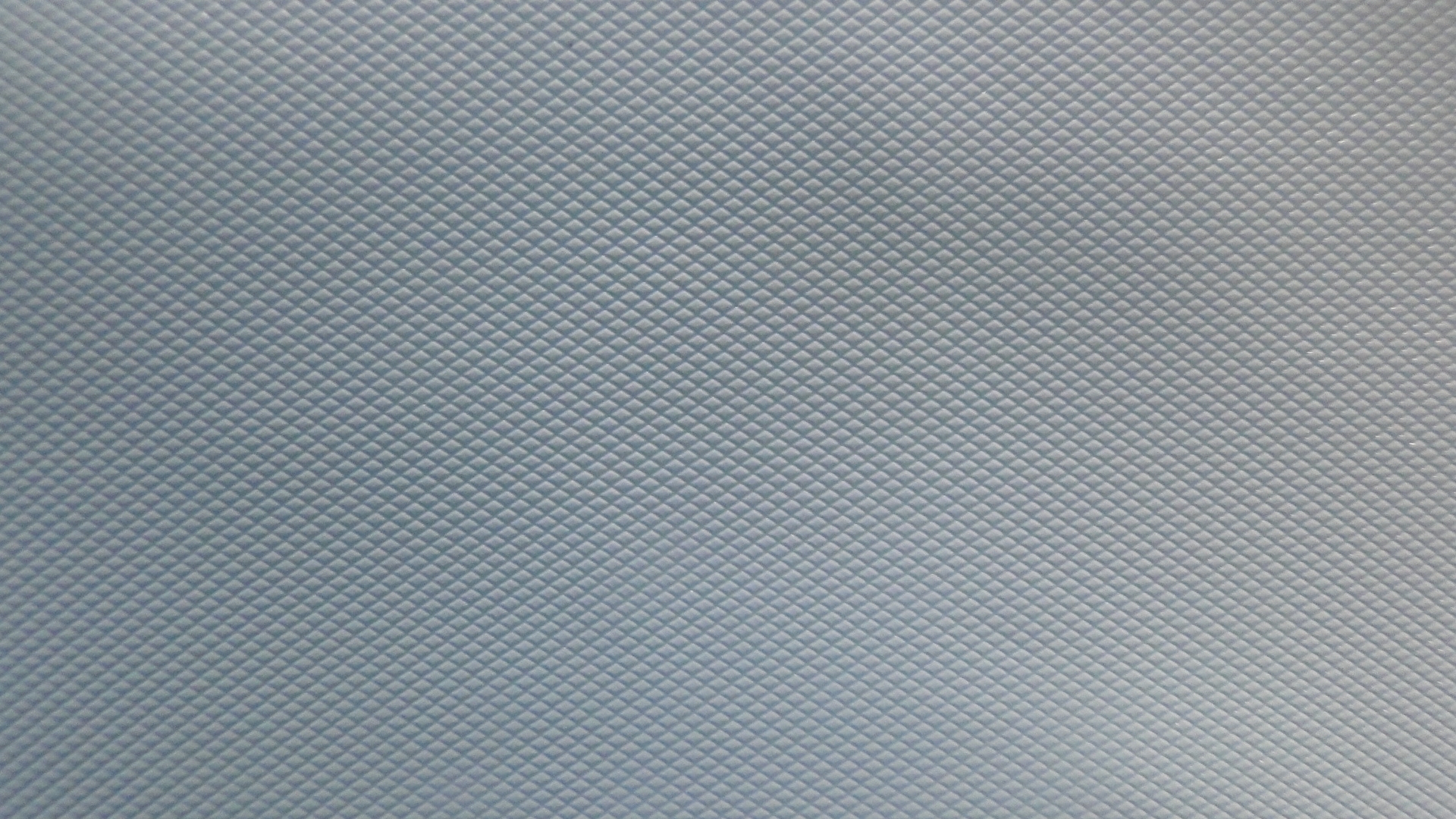

Melt embossing process has a wide range of applications, such as PE film for baby diaper, sanitary napkin, inconvenience products, pet pad, disposable bedsheet, medical dressings, grown, gloves, shoes cover, rubber release film, table cloth, shower curtain, and so forth.

Melt embossed PE film are mostly used as hygiene backsheet film for baby diaper, sanitary napkin, adult diaper, underpad. We are most experienced in manufacturing cast embossed film machine to meet exact processing needs for hygiene films and PE film for disposable medical products such as surgical gowns, isolation gowns.

*TECHNICAL DATA

| Model No. | Screw Dia. | Die Width | Film Width | Film Thickness | Line Speed |

| FME120-1600 | ¢120mm | 1900mm | 1600mm | 0.02-0.15mm | 200m/min |

| FME125-2000 | ¢125mm | 2300mm | 2000mm | 0.02-0.15mm | 200m/min |

| FME135-2500 | ¢135mm | 2800mm | 2500mm | 0.02-0.15mm | 200m/min |

Remarks: Other sizes of machines are available upon request.

*FEATURES & ADVANTAGES

1) Any film width (up to 4000mm) at customer’s disposable.

2) Easy to change embossing roll for various emboss patterns.

3) Very low variation of film thickness

4) In-line film edge trim and recycling

5) In-line extrusion coating is optional

6) Auto film winder with different size of air shaft

Product detail pictures:

Related Product Guide:

Cooperation

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for China Factory for Microporous Film Production Line - Cast Embossed Film Line, Hygiene Film Line – Wellson , The product will supply to all over the world, such as: Hamburg, Manila, Juventus, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!