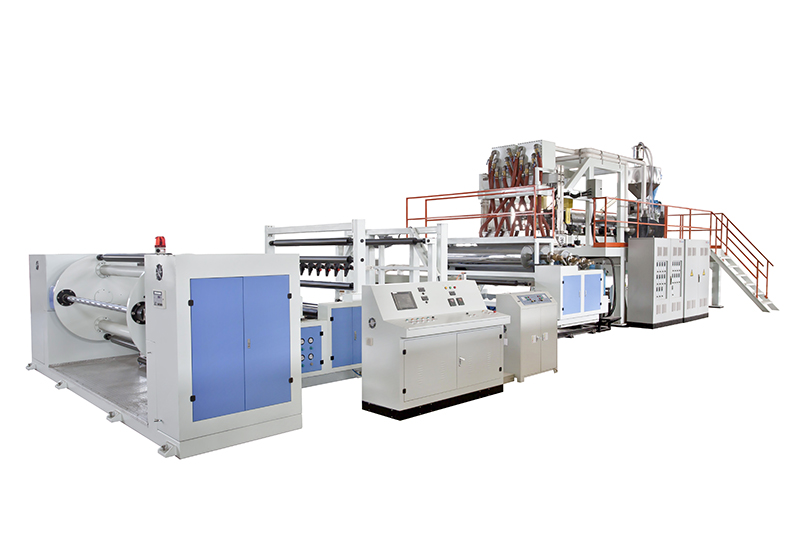

Best-Selling Coating And Laminating Line - Hot Melt Glue Coating Laminating Machine – Wellson

Best-Selling Coating And Laminating Line - Hot Melt Glue Coating Laminating Machine – Wellson Detail:

*INTRODUCTION

Hot melt glue laminating and coating machine is mainly composed of hot melt glue spray, servo motor-controlled winder and unwinder, servo motion controller, servo automatic rectifying system and human-computer interface control, etc. Since it is featured with stable tension control under full servo tension control system, new complex technique of dot glue or spread coating and small amount of glue on laminated film, it is then widely used to laminate TPU film, PE film, and breathable film with textile or nonwoven.

There are three main laminating technologies for hot melt adhesive lamination: gravure roller coating, slot die coating and spray coating which depends on the specific materials and coating weight. Turret unwind and rewind systems are available for high speed non-stop production.

*Machine Details

Product Width: any option from 500mm to 2500mm, upon request

Laminating Method: fiber spray

Substrates: nonwoven, woven fabric, film, paper

Diameter of Unwinding: Φ1200mm max.

Diameter of Winding: Φ 1000mm max.

*Application

The hot melt glue laminating machine is suitable for garment, hygiene and medical applications, especially disposable products and health protective products, such as disposable table cloth, diapers for babies and adults, sanitary pads, medical tapes and articles for pets, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for Best-Selling Coating And Laminating Line - Hot Melt Glue Coating Laminating Machine – Wellson , The product will supply to all over the world, such as: Singapore, Tunisia, Jamaica, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.