100% Original Vacuum Perforated Pe Film Machine - TPU Cast Film Line for Hot Melt Film, Laminating Film – Wellson

100% Original Vacuum Perforated Pe Film Machine - TPU Cast Film Line for Hot Melt Film, Laminating Film – Wellson Detail:

*INTRODUCTION

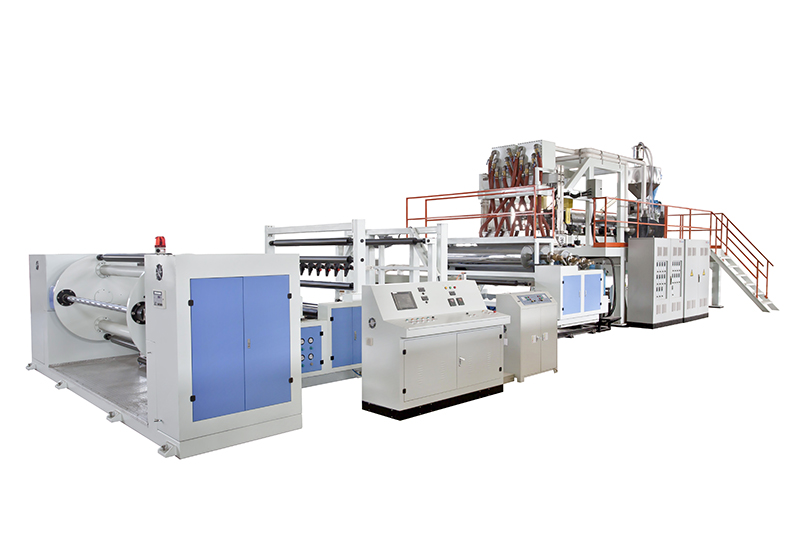

TPU cast film line is well designed to produce TPU hotmelt film, TPU laminating film and highly transparent TPU film. The line accept both high-temperature and low-temperature TPU resins, and it can run different types of TPU film products.

TPU cast film extrusion line is equipped with high-performance extruders to best meet the processing requirements of thermoplastic polymer. The temperature control system has high accuracy to ensure high quality TPU film product as well as best power-saving. The unwinder accept to run release film or release paper as the backing materials for TPU film rolls. Our technical experiences and know-how will be a plus to the line solution to our customers’ investment.

The manufacturing process of TPU cast film line includes polymers handling, extrusion, filtering, flat T die, casting, down-stream processing and winding. The extruders are specially designed for the processing thermoplastic polymer with full consideration of its elastic properties. The guiding rollers are coated with Teflon for anti-sticky purpose. The complete production line is integrated in the PLC control system for easy and quick operation. The machine also is designed by the modular concept for easy ocean transportation and installation, easy wiring and few failures.

*Advantages & Features

1) The size of machine can be customer made upon request.

2) All the rollers are anti-sticky with Teflon coating, suitable for TPU film

3) Equipped with unwinder for release paper substrate

4) The machine is able to produce thick TPU sheet and max thickness can be 0.50mm

*Application

Thermoplastic polyurethane is referred to as TPU, is a flexible film with high elongation and properties and characteristics that are superior to most polyolefin films. Thus TPU is often an excellent choice for more demanding film applications. TPU film products has various

TPU film products has various applications as below:

1) Garment Industry: sportswear, swim suit, underwear, hat, shoes

2) Medical Industry: gloves, surgical dressings, bedsheet

3) Umbrella, handbag, leather bag, suitcase, tent, sports kit

4) Car decoration materials, construction materials

*Technical Data

| Model No. | Screw Dia. | Die Width | Film Width | Film Thickness | Line Speed |

| WS-120-1600 | ¢120mm | 1900mm | 1600mm | 0.02-0.15mm | 180m/min |

| WS-125-2000 | ¢125mm | 2300mm | 2000mm | 0.02-0.15mm | 180m/min |

| WS-135-2500 | ¢135mm | 2800mm | 2500mm | 0.02-0.15mm | 180m/min |

Product detail pictures:

Related Product Guide:

Cooperation

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for 100% Original Vacuum Perforated Pe Film Machine - TPU Cast Film Line for Hot Melt Film, Laminating Film – Wellson , The product will supply to all over the world, such as: Mongolia, Greece, Ukraine, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.